Measured vs Combinational Error

Tech Note

Astute system engineers must determine an acceptable error budget associated with their system design and purchase system components with appropriate accuracy specifications. The accuracy specification attributed to an electronic component is the indicator of how much error can be expected in a particular component.

For example, a signal-conditioning component with an error of 1%, means that one can expect this unit to read 99% to1.01% accurately; whereas, a 0.05% accuracy specifications means the unit reads 99.95% to1.0005% accurately. Too often, the combinational effects of "accuracy specifications" are overlooked.

For example, consider the following two cases.

(1) Two modules in series each with 0.02% accuracy used to read one signal will result in a combined accuracy specification of 0.04%, [(0.998)*(0.998) = 0.996].

(2) Three variables are measured with 0.05% accurate modules and used in the computation V1 / (V2*V3), which has a worst-case accuracy of 0.15%, [0.9995/(1.0005*1.0005)].

Clearly, the interconnecting topology of measurement modules and how measured values are used in computations have a significant impact on the total system error.

Using instrumentation modules with low "accuracy specifications" (meaning high accuracy) can minimize system errors.

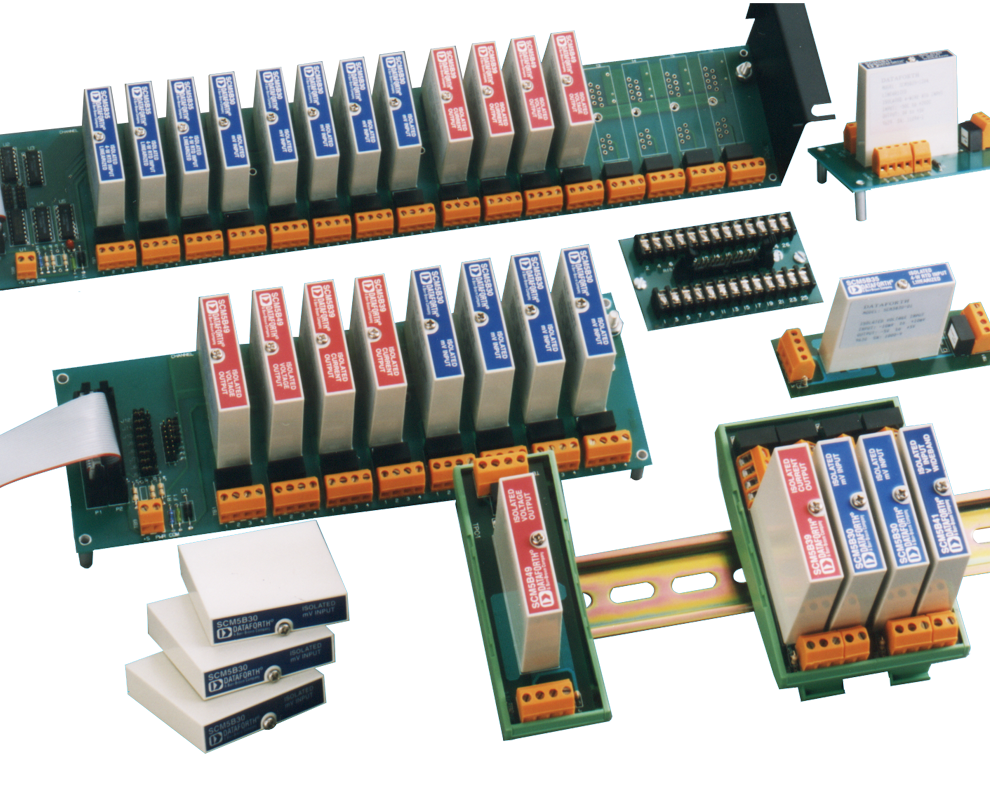

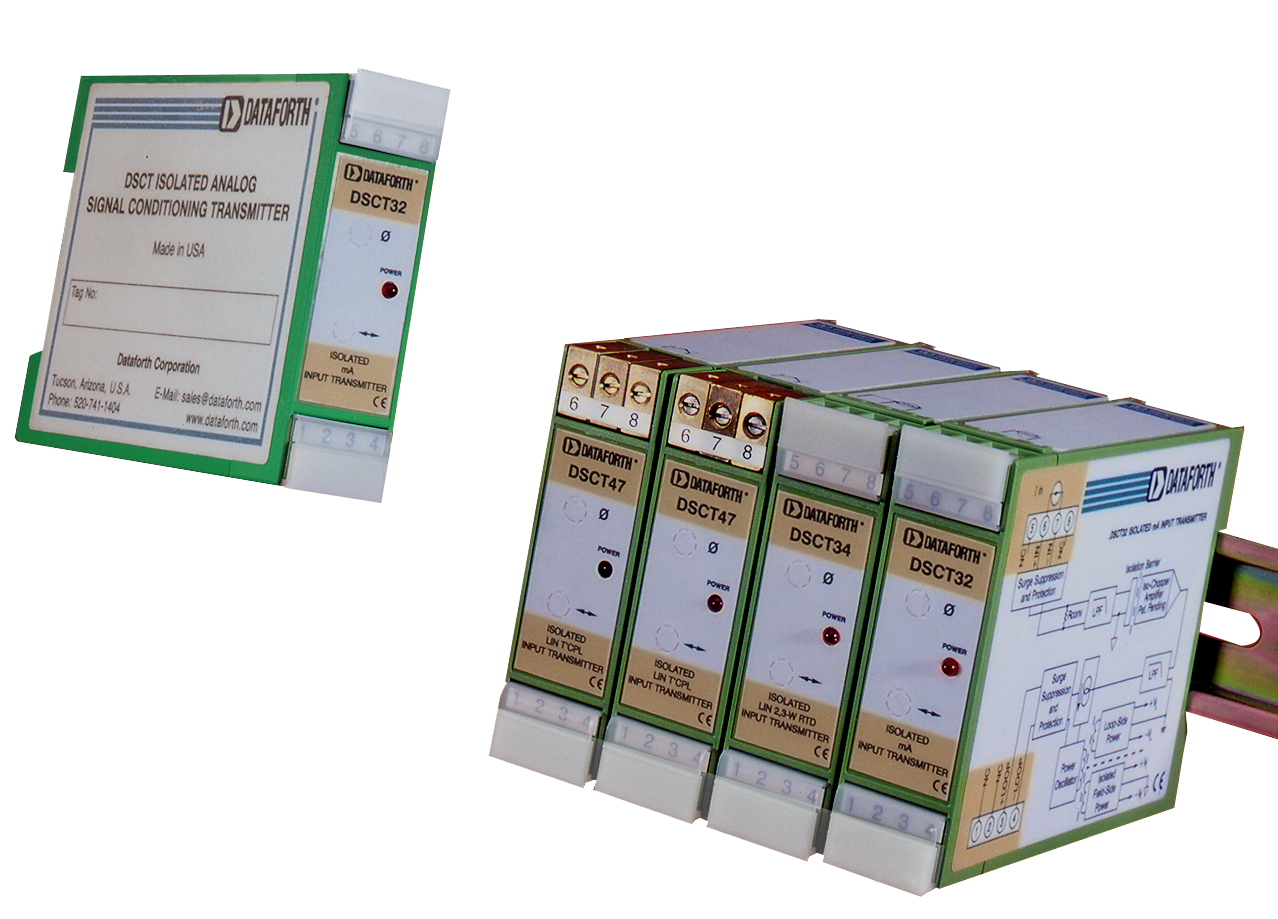

Dataforth, Inc offers Signal Conditioning Modules with the highest ratio of "accuracy to cost" merit figure in their class. For example, our DSCA47 linearized thermocouple input modules provide overall accuracies to 0.07% (0.35C). Please visit our website specs for a more detailed review.

Remember, our Application Engineers can assist you with signal conditioner selection over the phone or via fax and email. Call us at our manufacturing facility in Tucson at 520-741-1404 (fax 520-741-0762) or Email us at support@dataforth.com.

For example, a signal-conditioning component with an error of 1%, means that one can expect this unit to read 99% to1.01% accurately; whereas, a 0.05% accuracy specifications means the unit reads 99.95% to1.0005% accurately. Too often, the combinational effects of "accuracy specifications" are overlooked.

For example, consider the following two cases.

(1) Two modules in series each with 0.02% accuracy used to read one signal will result in a combined accuracy specification of 0.04%, [(0.998)*(0.998) = 0.996].

(2) Three variables are measured with 0.05% accurate modules and used in the computation V1 / (V2*V3), which has a worst-case accuracy of 0.15%, [0.9995/(1.0005*1.0005)].

Clearly, the interconnecting topology of measurement modules and how measured values are used in computations have a significant impact on the total system error.

Using instrumentation modules with low "accuracy specifications" (meaning high accuracy) can minimize system errors.

Dataforth, Inc offers Signal Conditioning Modules with the highest ratio of "accuracy to cost" merit figure in their class. For example, our DSCA47 linearized thermocouple input modules provide overall accuracies to 0.07% (0.35C). Please visit our website specs for a more detailed review.

Remember, our Application Engineers can assist you with signal conditioner selection over the phone or via fax and email. Call us at our manufacturing facility in Tucson at 520-741-1404 (fax 520-741-0762) or Email us at support@dataforth.com.

Was this content helpful?

Thank you for your feedback!