Galvanic Isolation

Tech Note

In today’s modern world of electronic products, the battery consumable market is booming. Battery technology for the consumer market has made significant progress over the past 200 years. The birth of battery technology is credited to the Italian physicist Luigi Galvani who, in 1780, discovered that a frog’s leg would “twitch” when brass hooks attached to the muscle were touched to an iron plate. He named this phenomena “animal electricity”.

Later in 1800, the Italian physicist Alessandro Volta capitalizing on Galvani’s frog experiment, invented the first recorded battery using zinc and copper electrodes separated in a solution of salt water. Next, in 1859 (145 years ago) the French physicist Gaston Plante developed the first rechargeable lead-acid battery technology, which is still in use today.

The historical evolution of commercial batteries has seen many major milestones since the "frog" experiment. Some of which are: the D-size Zinc-Carbon battery in 1889, the Nickel-Cadmium battery in 1899, the Alkaline battery in 1959, the Lithium battery in 1967, the Nickel-Metal-Hydrogen (NiMH) battery in 1990, the Lithium-ion polymer battery in 1999, the Direct-Methanol Fuel Cell in 2004.

Archaeologists, in 1936, discovered a clay vessel containing iron and copper rods. The structure of this vessel resembles a crude battery, which is believed to have contained vinegar as an electrolyte and was used in a crude gold electroplating system. The jars are about 2000 years old from the Parthian period!

Using batteries is one technique for developing circuits that are isolated. Designing "Galvanic Isolation" into your products is just as effective. Dataforth's signal conditioners are designed with full 3-way isolation - the signal path, the field circuit power supply and the system circuit power supply are each isolated!

Matter of fact, using Dataforth's isolated signal conditioners are an excellent way to measure batteries! Many customers use Dataforth's isolated signal conditioning modules, SCMs, to measure batteries cell-to-cell and rely on the inherent high common mode rejection to protect sensitive monitoring and control devices. Moreover, Dataforth's SCM5B40 family provides 200 megohm input resistance in addition to a 160dB common mode rejection ratio!

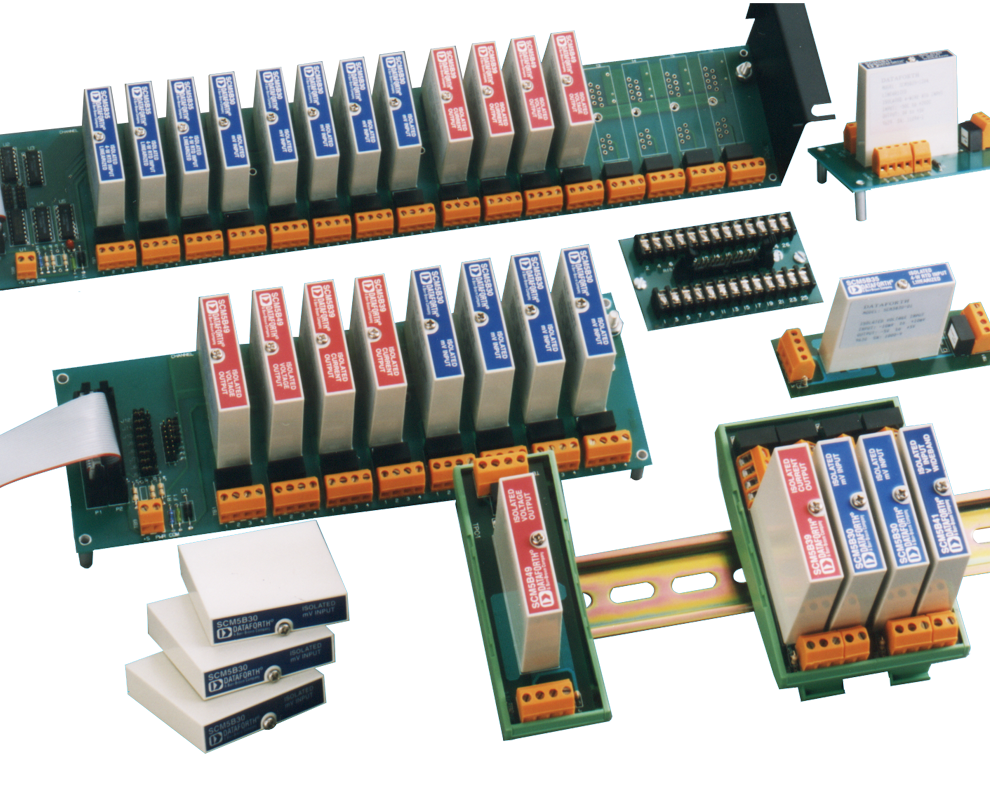

SCM5B Family

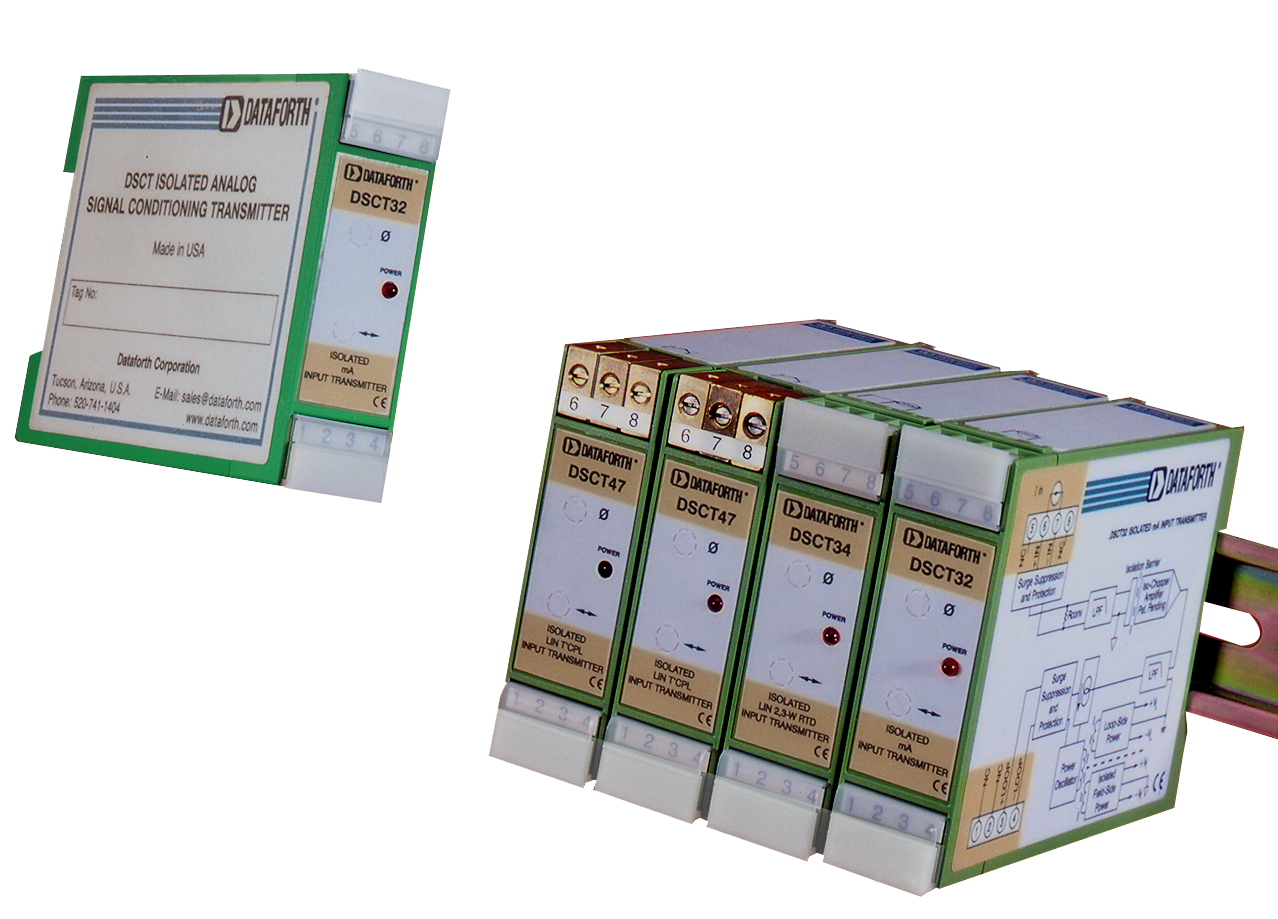

If you use them or are involved in battery or fuel cell design, or manufacture, Dataforth has a signal conditioner that can protect, amplify (or attenuate), isolate and filter your valuable measurement and control data!

Remember, our Application Engineers can assist you with signal conditioner selection over the phone or via fax and email. Call us at our manufacturing facility in Tucson at 520-741-1404 (fax 520-741-0762) or Email us at support@dataforth.com.

Later in 1800, the Italian physicist Alessandro Volta capitalizing on Galvani’s frog experiment, invented the first recorded battery using zinc and copper electrodes separated in a solution of salt water. Next, in 1859 (145 years ago) the French physicist Gaston Plante developed the first rechargeable lead-acid battery technology, which is still in use today.

The historical evolution of commercial batteries has seen many major milestones since the "frog" experiment. Some of which are: the D-size Zinc-Carbon battery in 1889, the Nickel-Cadmium battery in 1899, the Alkaline battery in 1959, the Lithium battery in 1967, the Nickel-Metal-Hydrogen (NiMH) battery in 1990, the Lithium-ion polymer battery in 1999, the Direct-Methanol Fuel Cell in 2004.

Archaeologists, in 1936, discovered a clay vessel containing iron and copper rods. The structure of this vessel resembles a crude battery, which is believed to have contained vinegar as an electrolyte and was used in a crude gold electroplating system. The jars are about 2000 years old from the Parthian period!

Using batteries is one technique for developing circuits that are isolated. Designing "Galvanic Isolation" into your products is just as effective. Dataforth's signal conditioners are designed with full 3-way isolation - the signal path, the field circuit power supply and the system circuit power supply are each isolated!

Matter of fact, using Dataforth's isolated signal conditioners are an excellent way to measure batteries! Many customers use Dataforth's isolated signal conditioning modules, SCMs, to measure batteries cell-to-cell and rely on the inherent high common mode rejection to protect sensitive monitoring and control devices. Moreover, Dataforth's SCM5B40 family provides 200 megohm input resistance in addition to a 160dB common mode rejection ratio!

SCM5B Family

If you use them or are involved in battery or fuel cell design, or manufacture, Dataforth has a signal conditioner that can protect, amplify (or attenuate), isolate and filter your valuable measurement and control data!

Remember, our Application Engineers can assist you with signal conditioner selection over the phone or via fax and email. Call us at our manufacturing facility in Tucson at 520-741-1404 (fax 520-741-0762) or Email us at support@dataforth.com.

Was this content helpful?

Thank you for your feedback!