Linearity and Conformity

Tech Note

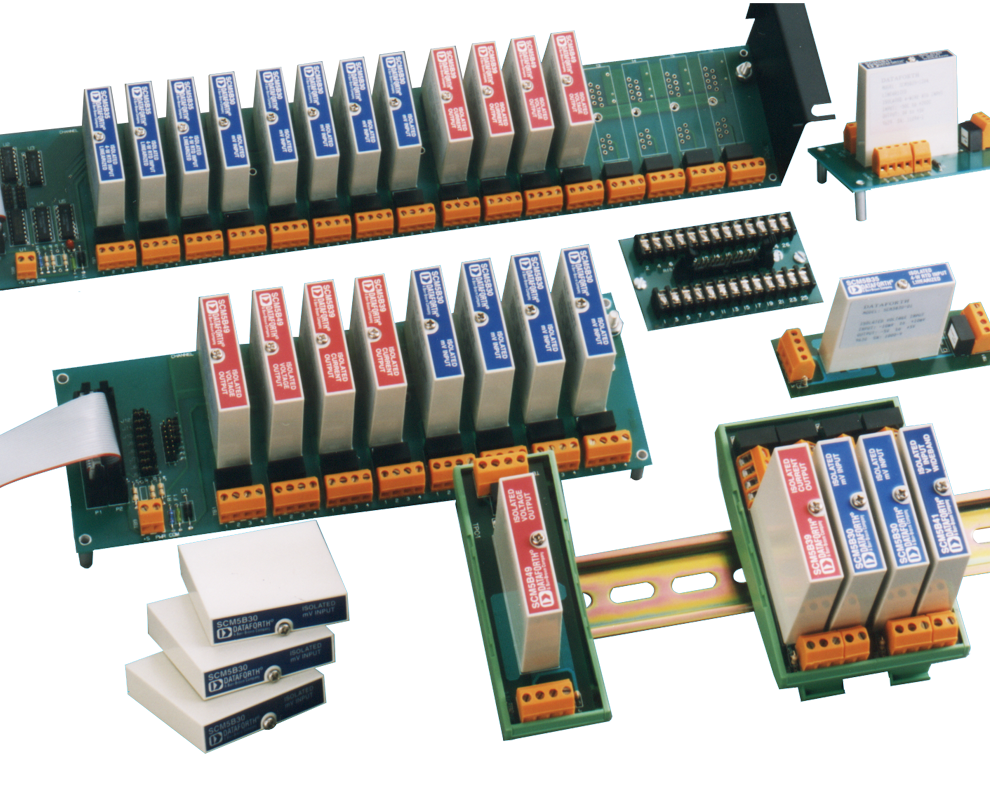

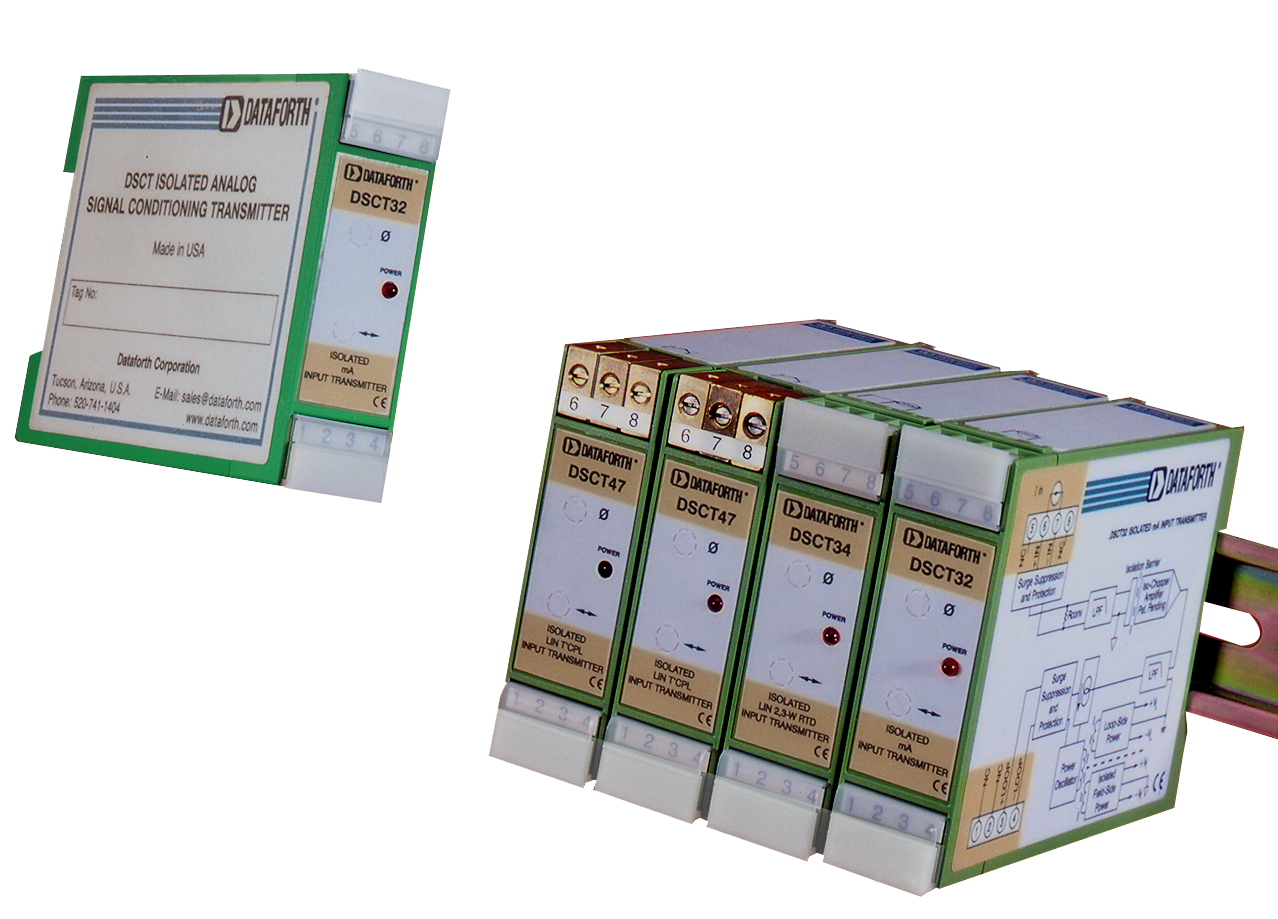

Data acquisition and process control systems function more efficiently and are easier to install if their field inputs are supplied by sensor signal conditioning modules which have linear transfer functions. A linear transfer function means that outputs of a device are a "straight line" response to the inputs. This allows the receiving data acquisition and control systems to directly interpret field information by assigning the data a linear scale factor such as gallons-per-minute (gpm) per volt, degrees per milliamp, psi per volt, etc.

Many field sensors such as Thermocouples, Resistance Temperature Devices (RTDs), and Thermistors, have non-linear outputs and their unconditioned data must be linearized and scaled by the receiving devices. This linearizing of field data requires additional overhead in the receiver’s processor. Data acquisition and process control systems that utilize "pre-conditioned" field inputs, which have already been linearized, scaled, filtered, and isolated are free of this expensive computational overhead, are easier to upgrade, and more cost effective overall.

Linearity specifications define how close any set of data approximates a straight line. Conformity specifications, on the other hand, define how close a set of data approximates a specific functional curve (e.g., cubic, exponential, logarithmic, etc.).

Both linearity and conformity specifications have three category types:

All specifications for linearity or conformity are established by averaging measurements taken by traversing the full range in each direction at least twice.

Many field sensors such as Thermocouples, Resistance Temperature Devices (RTDs), and Thermistors, have non-linear outputs and their unconditioned data must be linearized and scaled by the receiving devices. This linearizing of field data requires additional overhead in the receiver’s processor. Data acquisition and process control systems that utilize "pre-conditioned" field inputs, which have already been linearized, scaled, filtered, and isolated are free of this expensive computational overhead, are easier to upgrade, and more cost effective overall.

Linearity specifications define how close any set of data approximates a straight line. Conformity specifications, on the other hand, define how close a set of data approximates a specific functional curve (e.g., cubic, exponential, logarithmic, etc.).

Both linearity and conformity specifications have three category types:

- Independent

- Terminal-based

- Zero-based

All specifications for linearity or conformity are established by averaging measurements taken by traversing the full range in each direction at least twice.

Was this content helpful?

Thank you for your feedback!